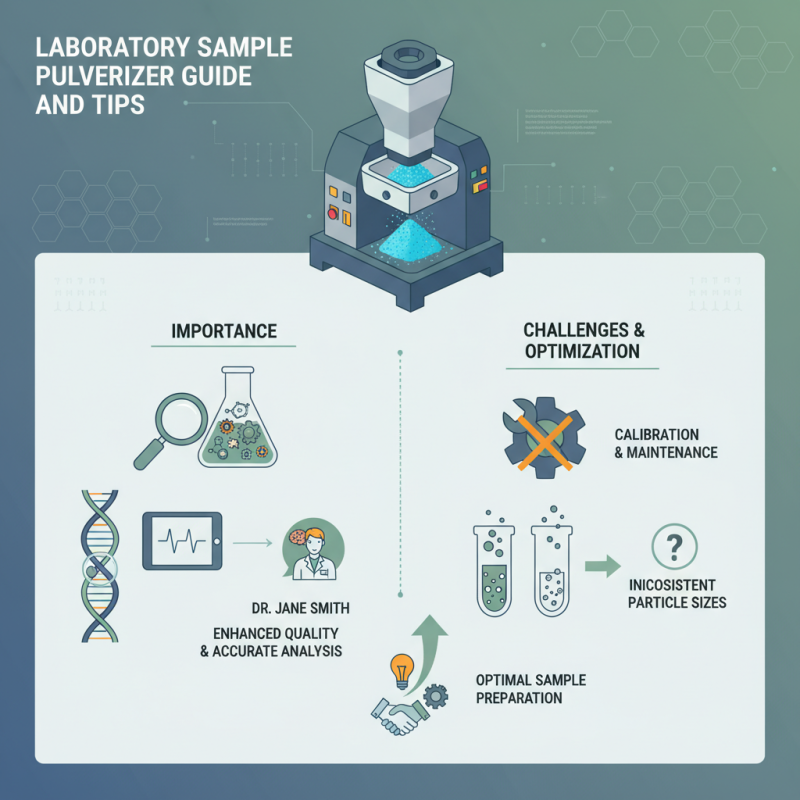

In the realm of sample preparation, the laboratory sample pulverizer plays a crucial role. According to recent industry reports, these devices have become essential in various fields, from materials science to pharmaceuticals. They ensure materials are properly crushed and homogenized for accurate analysis.

Dr. Jane Smith, a leading expert in laboratory instrumentation, emphasizes the importance of selecting the right pulverizer. She states, "A well-chosen laboratory sample pulverizer can significantly enhance the quality of your results." This sentiment resonates across laboratories aiming for precision in their testing processes.

However, challenges still exist. Many users struggle with the calibration and maintenance of their pulverizers. Inaccurate settings can lead to inconsistent particle sizes. While advancements continue, it's vital to reflect on how to best utilize this equipment. The journey towards optimal sample preparation is ongoing, filled with learning opportunities.

Digital laboratory sample pulverizers play a crucial role in various research and industrial applications. These instruments ensure that samples are ground to a consistent particle size. This uniformity is essential for accurate testing and analysis. Any variation in sample size can lead to unreliable results. Thus, choosing the right pulverizer is imperative.

Understanding how these pulverizers work can clarify their importance. Most models utilize advanced digital technology for precise control. Users can set specific parameters for grinding. This capability allows for the tailoring of processes to meet different sample requirements. However, user error can occur, especially when settings are not carefully monitored. Sometimes, operators may overlook calibration. A fine-tuned apparatus can yield more reliable data.

The dimensions of the sample and the desired fineness are factors that influence you. Even small miscalculations can affect the outcome. Experimenting with different settings might seem beneficial. Still, you must reflect on the results. It’s vital to remain vigilant about maintaining equipment and following best practices. Observing the equipment’s performance and making adjustments can enhance reliability significantly.

When selecting a digital pulverizer for laboratory use, specific features stand out. First, consider the grinding capacity. A model that can process a range of sample sizes will offer more versatility. Look for an adjustable grinding speed. Different materials require distinct speeds for optimal results.

Another essential feature is the materials used in the construction. Stainless steel or heavy-duty plastic offers durability and ease of cleaning. Furthermore, check for safety features. Automatic shut-off mechanisms can prevent overheating and potential accidents. It’s also wise to look for noise levels. Some devices may be extremely loud, which can disrupt work environments.

Lastly, consider ease of use. A user-friendly interface can save time and reduce errors. Digital displays should be clear and easy to read. However, not all digital models provide intuitive controls. Always reflect on how the design fits your workflow. Balancing features and usability can be challenging but is crucial for an efficient setup.

Choosing the right pulverizer for your laboratory needs can feel overwhelming. The first step is to identify your material's properties. Harder materials require robust machines, while softer samples may need less power. According to a report by the International Journal of Material Science, sample preparation is crucial for accurate results in material testing.

When selecting a pulverizer, consider the particle size you need. Fine grinding often requires high-speed options. A study published in the Journal of Analytical Chemistry emphasizes the necessity of uniform particle size for reliable experiments. Pay attention to the grinding mechanism as well. Some machines use blades, while others rely on balls or disks. Each method offers different advantages and disadvantages. A mismatch could lead to poor sample quality.

Budget constraints also play a significant role. High-end pulverizers come with advanced features but can be costly. It may be tempting to choose the cheapest model, but this decision can compromise quality. Sometimes, investing more upfront saves you in the long run, allowing consistent results. Reflect on your priorities carefully. The perfect pulverizer exists, but finding it requires thoughtful consideration.

Maintaining your pulverizer is essential for optimal performance. Regular inspection helps you identify potential issues before they escalate. Pay attention to wear and tear, especially on grinding plates. These parts are critical to achieving the right particle size. A small chip can affect the overall efficiency.

Cleaning is another vital aspect. Dust and residue can accumulate quickly. It’s important to clean the unit after each use. This practice prevents cross-contamination of samples. Use a brush or vacuum to remove debris promptly. Neglecting this can lead to flawed results.

Check the motor and belts regularly. Look for signs of fraying or excessive wear. These may require immediate attention. If you notice strange noises, stop using the machine. Ignoring unusual sounds can lead to serious damage. Reflect on your maintenance routine. Are you investing enough time? Good practices today yield better performance tomorrow.

| Parameter | Value | Maintenance Tips |

|---|---|---|

| Feed Size | < 10 mm | Regularly check and adjust feed size. |

| Speed | 3000 RPM | Monitor speed settings frequently. |

| Power Consumption | 1.5 kW | Ensure efficient power usage to prevent overheating. |

| Dust Extraction | Yes | Regular filter cleaning and replacement recommended. |

| Number of Blades | 6 | Inspect blades for wear and tear periodically. |

| Cooling System | Air-Cooled | Ensure proper air circulation around the unit. |

Using a digital sample pulverizer requires careful attention to detail. Common mistakes can lead to unsatisfactory results. One typical error is neglecting to calibrate the device. Proper calibration ensures accuracy. Failing to do this can skew your data significantly. It’s easy to overlook, but it’s crucial.

Another mistake is overloading the pulverizer. Putting too much sample can cause jams or uneven grinding. Instead, use smaller batches. This allows for better consistency. Always monitor the texture during the process. If it doesn’t look right, stop and assess.

Tips for better results include using dry samples. Moisture can affect the pulverization process. Moreover, clean your device regularly. Residue can contaminate your next sample. At times, it’s helpful to take notes during each session. This documentation assists in refining your approach. Mistakes are part of learning, but reflection is key. Always ask yourself what works and what doesn’t.