Choosing the right plastic clamshell packaging for your products can be challenging. This decision affects your product's safety and market appeal. Plastic clamshell packaging offers visibility and protection, crucial aspects for consumers. It allows customers to see the product while ensuring it stays intact during transportation.

However, you must consider various factors. Dimensions, materials, and closure types can vary significantly. Some clamshells are sturdy and reusable, while others are lightweight and designed for single use. Finding the perfect balance is essential. You may feel overwhelmed by the numerous options available.

Understanding your target audience is key. What do they value? Is it sustainability, affordability, or aesthetics? Feedback from customers can guide your selection process. Reflecting on previous choices is also vital. Did they resonate with consumers? Each decision matters, influencing both sales and brand reputation. Recognizing the impact of your packaging choice is the first step in making a well-informed decision.

Choosing the right plastic clamshell packaging involves several key factors. First, you need to consider the type of product you are packaging. Different products have varying requirements for protection and presentation. For fragile items, a thicker material might be necessary. A lightweight option could work for more durable products. There’s no one-size-fits-all solution here.

Next, think about the size and shape of your product. Clamshells can be custom-made to fit unique items. Ensure that the layout maximizes space without compromising security. You want to avoid wasting materials. Remember, a snug fit can prevent damage. Also, ponder over the design. Clear packaging showcases your product well. However, creative prints could enhance brand identity.

Don’t forget to reflect on sustainability. Eco-friendly materials are gaining popularity. They can boost your brand image but might increase costs. Always weigh the trade-offs. Finally, consider your budget. While cheaper options exist, they may lack quality. A balance between cost and durability is crucial. It's vital to learn from each choice you make. Each decision shapes your product's success.

When selecting the right plastic clamshell packaging, understanding the types of materials available is critical. Common choices include PET, PVC, and PS. Each type has distinct characteristics, influencing durability, clarity, and recyclability.

PET, or polyethylene terephthalate, offers excellent strength and transparency. It's often used for food packaging because it's safe for direct contact with edible products. PVC, polyvinyl chloride, is cost-effective and flexible. However, it may not be the best choice for eco-conscious brands. PS, or polystyrene, is lightweight and easy to mold but can be less durable.

Tips: Consider your product's needs. If longevity is vital, opt for PET. For cost-sensitive projects, PVC may suffice. Pay attention to recyclability.

Choosing the right material can feel daunting. It helps to weigh the benefits and drawbacks of each option. Remember, clarity may catch a customer's eye, but durability keeps the product secure. Reflect on what's most important for your packaging choice.

When choosing clamshell packaging, product compatibility is crucial. A report by Smithers Pira highlights that improper packaging can lead to a 15% increase in product damage during shipping. This statistic signifies that not all products fit well in clamshell designs. Selecting the right type is essential to ensure protection.

Different products require specific clamshell designs. For example, fragile items like glassware need thicker plastic. Conversely, lightweight items can use thinner materials. A survey from Packaging Strategies reported that 73% of businesses experienced returns due to inadequate packaging. This shows the importance of assessing product features before selecting a clamshell design.

Visual appeal is also a significant factor. The right design can enhance product visibility while minimizing damage risk. However, finding a balance is challenging. Overly rigid designs may not accommodate odd shapes, while softer designs might risk breakage. According to Packaging World, 35% of consumers prioritize durability over aesthetics. This statistic emphasizes the necessity of evaluating product compatibility deeply.

Clamshell packaging offers a versatile solution for various products. However, its environmental impact cannot be overlooked. Many clamshells are made from plastic, which can take hundreds of years to decompose. This prolonged lifespan leads to significant waste accumulation in landfills and oceans. Moreover, the production process itself contributes to greenhouse gas emissions, raising concerns about sustainability.

Choosing eco-friendly options is crucial. Some manufacturers are now using recycled materials for clamshells. These alternatives are a step toward reducing reliance on new plastics. However, the availability of truly sustainable clamshells remains inconsistent. Not all recycled plastics are created equal, and not all deliver the required performance.

Consumers are becoming more aware of these issues. They seek alternatives that balance protection and environmental responsibility. Each decision we make impacts the planet. It’s important to reflect on the choices we have in packaging. By considering biodegradable materials, we can significantly reduce the ecological footprint of clamshell packaging. Thoughtful choices can lead us toward a greener future.

| Criteria | Standard Options | Sustainable Options | Environmental Impact |

|---|---|---|---|

| Material Type | Polyethylene (PE) | Recyclable PET | Higher recyclability rate reduces landfill impact |

| Recycling Availability | Limited | Widely available | Encourages recycling behaviors |

| Production Process | Energy-intensive | Eco-friendly methods used | Lower carbon footprint |

| Cost | Generally lower | Slightly higher due to sourcing | Investing in sustainability |

| Durability | Moderate | Similar to standard | Same level of protection for products |

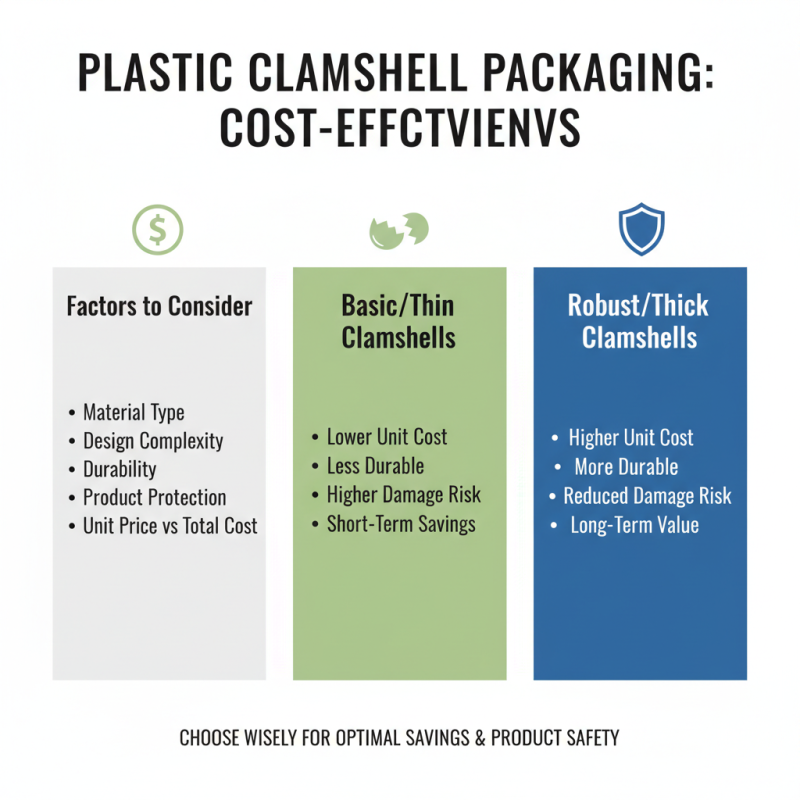

When evaluating the cost-effectiveness of plastic clamshell packaging, consider several factors. Clamshells come in various materials and designs, affecting the overall price. A simple, thin option might save money upfront but can be less durable. A more robust design could offer better protection, reducing product losses.

It’s important to weigh the long-term costs. Cheaper packaging might lead to higher shipping costs due to damage. Additionally, the impact on brand perception should not be overlooked. Poor-quality packaging can reflect badly on your product. Customers expect quality from the moment they see the packaging.

Conducting a thorough cost analysis is essential. Calculate the initial costs alongside potential losses from damaged products. Factor in the environmental impact too. Eco-friendly options may have higher upfront costs but can improve your brand's reputation. Balancing cost with quality can be tricky, but it’s necessary for sustainable success.